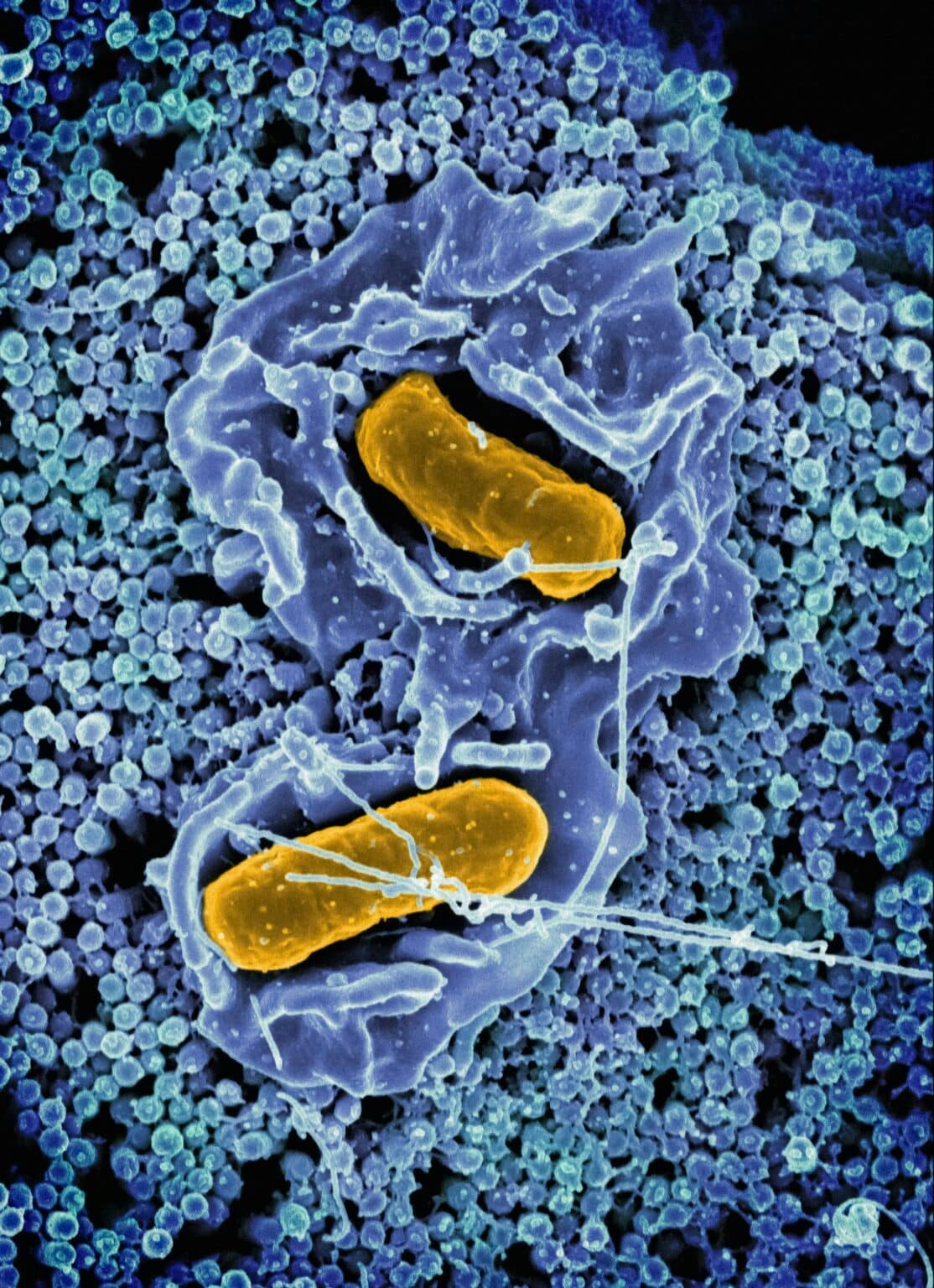

Salmonella, a bacterium commonly associated with moisture-rich foods, demonstrates remarkable persistence in low-water-activity (a<0.85) products like cookie fillings, crackers, peanut butter, and spices. This survival challenges traditional food safety assumptions about dry environments. Research reveals that the interplay between water activity, food composition, and temperature creates niches where pathogens can endure for months, necessitating stringent manufacturing controls.

Extended Persistence in Cookie and Cracker Fillings

Studies confirm Salmonella survives in cookie and cracker sandwiches far longer than previously assumed. When inoculated into chocolate or peanut butter crème fillings (initial water activity: ~0.30), Salmonella persisted for at least 182 days (6 months) at 25°C, even at low initial populations (0.36–3.6 log CFU/g). Similarly, in cracker sandwiches with peanut butter- or cheese-based fillings, survival lasted up to 182 days. The fillings’ low water activity equilibrated with the dry components over time (e.g., chocolate cookie bases reached a~0.38 within 15 days), creating a stable microenvironment for bacterial endurance. This extended persistence underscores the critical need to prevent contamination during ingredient sourcing and filling manufacture, as post-process elimination is exceptionally difficult.

Peanut Butter: Fat-Protected Survival

Peanut butter’s high fat content and unique water activity dynamics enhance Salmonella’s thermal resistance. At room temperature, peanut butter with a~0.45 exhibits increased heat tolerance compared to drier matrices like flour. When heated to 80°C, its water activity decreases sharply (from 0.45 to 0.04), creating a protective environment that significantly elevates Salmonella’s heat resistance. The D~80~-value (time required to reduce Salmonella by 90% at 80°C) in peanut butter is 17.0 minutes—over twice as long as in all-purpose flour under identical conditions. This property complicates thermal inactivation efforts. During baking experiments, peanut butter cookies required 15 minutes at 177°C to achieve a >5-log reduction of Salmonella, with detectable pathogens still present after shorter baking times.

Thermal Inactivation Challenges

Validated baking processes for low-moisture foods must account for Salmonella’s heat tolerance in specific matrices. For cookies, achieving a >5-log reduction requires precise time-temperature combinations:

- Hard cookies: ≥185°C for ≥16 minutes

- Soft cookies: ≥165.5°C for ≥22 minutes

Salmonella D-values in cookie dough increase significantly at lower temperatures—59.6 minutes at 60°C in hard cookie dough and 62.3 minutes at 60°C in soft cookie dough. The z-values (temperature increase needed to reduce D-value by 90%) further highlight this resilience: 14.5°C for hard cookies and 15.8°C for soft cookies. These metrics confirm that standard baking durations must be rigorously controlled to ensure safety.

Prevention Over Remediation

Since eliminating Salmonella after contamination in low-water-activity foods is exceptionally challenging, prevention remains paramount. Key measures include:

- Ingredient sourcing: Ensuring fillings and dry components (e.g., spices, peanut butter) are pathogen-free before use.

- Environmental control: Avoiding moisture introduction in processing facilities, which can promote Salmonella growth and spread.

- Process validation: Adhering to scientifically verified baking times and temperatures for specific product types.

The endurance of Salmonella in these environments transforms food safety protocols from reaction to prevention, demanding attentiveness at every manufacturing stage.