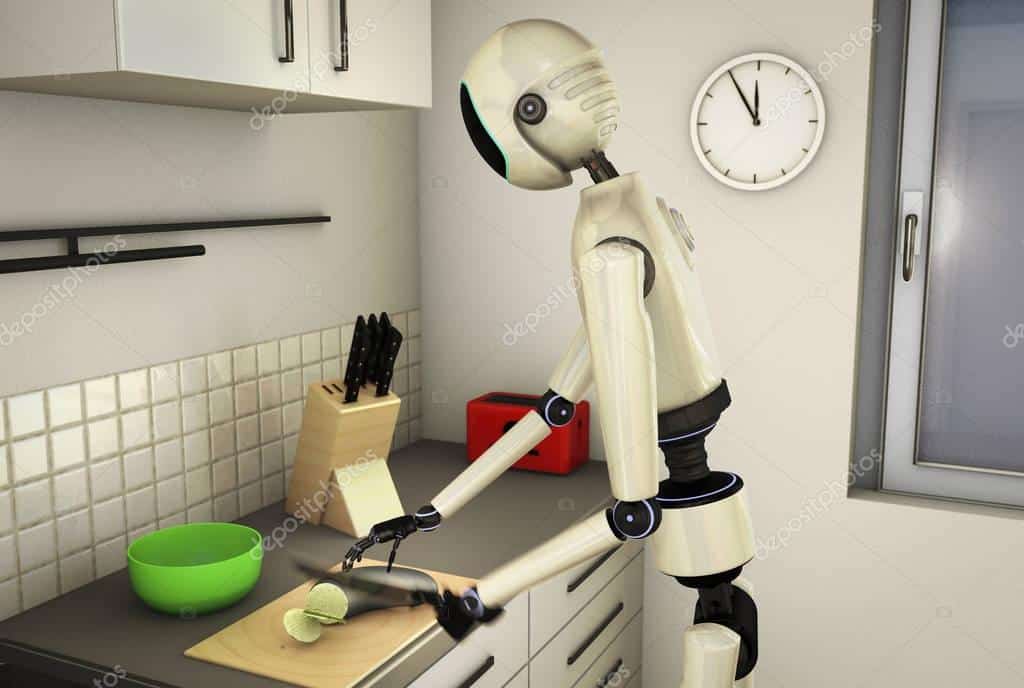

OK, so robots are still a few years off in the future, but there is a new wave of automated sanitation technology transforming restaurant kitchens: ultraviolet (UV) light-emitting robots designed to neutralize harmful pathogens on surfaces, equipment, and even fresh produce. These systems, leveraging UV-C light’s proven germicidal properties, are increasingly adopted by food establishments to bolster safety standards and reduce contamination risks.

How UV-C Technology Works

UV-C light, a wavelength within the ultraviolet spectrum, disrupts the DNA and RNA of bacteria, viruses, and molds, rendering them unable to replicate. Studies show it effectively inactivates pathogens like E. coli, Salmonella, and norovirus, common culprits of foodborne illness. Unlike chemical cleaners, UV-C leaves no residue and can sanitize hard-to-reach areas.

Restaurant-grade UV robots, often wheeled or mounted units, emit concentrated UV-C light across pre-programmed zones. Operators deploy them after manual cleaning, typically during off-hours to avoid human exposure, as UV-C can harm skin and eyes. Advanced models feature motion sensors that automatically shut off if a person enters the room.

Applications in Food Safety

In kitchens, these robots target high-touch surfaces, countertops, cutting boards, and utensil stations, as well as storage areas and appliances. Some systems also treat produce by exposing items like leafy greens or fruits to controlled UV-C doses, reducing microbial loads without chemicals or heat. Research from the Journal of Food Protection notes UV-C’s efficacy in extending shelf life and minimizing spoilage organisms.

Driving Adoption

The COVID-19 pandemic accelerated interest in UV sanitation as restaurants sought to reassure customers and meet heightened hygiene expectations. Chains like Chipotle and McDonald’s have tested UV robots for equipment cleaning, while cruise lines and hospitals pioneered their use years prior. Market analysts project the global UV disinfection sector to exceed $10 billion by 2028, with food service as a key growth area.

Challenges and Limitations

Despite advantages, UV-C systems require careful operation. Shadows, distance from the light source, or insufficient exposure time can compromise effectiveness. Surfaces must be free of organic debris, as dirt or grease can shield pathogens. Costs also pose a barrier: commercial UV robots range from $15,000 to $50,000, though leasing models are emerging.

Regulatory agencies like the FDA and CDC recognize UV-C as a supplemental tool but stress it cannot replace manual cleaning. The National Sanitation Foundation (NSF) certifies UV devices meeting specific safety and performance criteria, guiding restaurateurs in vetting systems.

Future Developments

Innovators are exploring hybrid robots combining UV-C with hydrogen peroxide vapor or electrostatic sprayers for broader coverage. Others aim to miniaturize units for real-time use during food prep, contingent on solving human-exposure risks.

As food safety demands evolve, UV robots represent a proactive step toward tech-driven hygiene. While not a standalone solution, their integration into sanitation protocols underscores the industry’s shift from reactive cleaning to preventive, science-backed systems. For restaurants, the goal remains clear: harnessing automation to protect patrons and reputations in an era of heightened scrutiny.

Commenting on this article, the nation’s leading Salmonella lawyer said, “Over time, the cost and complexity of these should begin to decrease. Then, the industry may start to see wider adoption and then reduced instances of foodborne illness.”